Technology

-

Plasma Ignition and Combustion Stabilization (PICS) Technology for Pulverized Coal Fired Boilers

PICS is a technology that can largely or totally reduce fuel oil consumption during boilers operations such as startup, shutdown, low load regulating operations. It can directly ignites pulverized coal with plasma arc at the initial stage of pulverized coal entering the burner when there is no flame in the furnace so as to realize oil-free start-up and oil-free combustion stabilization at low load.

PICS was first successfully put into commercial application in year 2000. After 25 years of development, it has now become a very mature technology, bringing significant economic benefits to customers.

Up to April, 2024, PICS has been applied on 1042 projects (1012 nos in China mainland and 31 nos in overseas). -

Mini Oil Ignition & Combustion Stabilization System

Mini-oil Ignition technology combines medium atomization and intensified gasification, applying the stable and high temperature (above 1800℃) oil torch with a small amount of fuel oil (20-250kg/h). When pulverized coal goes through the oil flame, it will soon absorb the heat and release volatile matters which immediately burst the coal particles and ignite. With staging combustion and unique air distribution, sufficient combustion can be realized at the beginning of ignition and the afterwards burning condition would be more stable.

-

Fuel Oil Free Power Plant

Dependent on plasma ignition and combustion stabilization system, LY Power developed Fuel Oil-free Power Plant firstly in world. It means all those oil facilities including oil guns, oil pumps, oil pipes, oil tanks, etc will not be required at all for these pulverized coal fired power units. After the application of PICS Oil-free Technology, the power plant will eliminate fuel oil completely. In May of 2008, LY Power completed the first demonstration PICS fuel oil-free project. By the end of 203 LY Power has applied PICS Oil-free Technology on around 170 oil-free power units of 70 power plants.

-

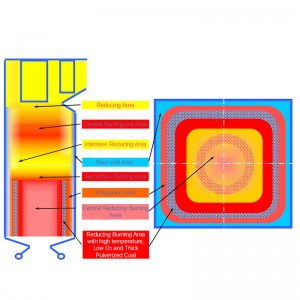

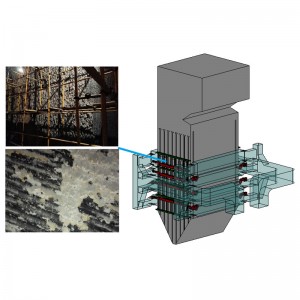

Dual-scale Low NOx Combustion Technology for Coal Fired Boilers

Dual-scale low NOx combustion is an integrated technology that combines many low NOx combustion technologies. Dual-dimension optimization is the most outstanding feature. It means optimizing combustion in space and process dimensions to realize a NOx reduction rate of up to 70%. Additionally, it has functions of anti-slaging, stabilizing combustion and preventing boiler efficiency loss. To the end of 2023, it has been applied on over 580 boilers.

-

Low NOx Emission Technology for CFB Boilers

The technology is based on the concept of high efficiency and low ammonia combustion inside the furnace, supplemented by SNCR denitration outside the furnace, and advocates the combination of rational use of fuel and pollution control technology, combustion control technology and flue gas denitrification technology, so as to achieve high efficiency and low cost of NOx ultra-low emission through comprehensive prevention measures.

-

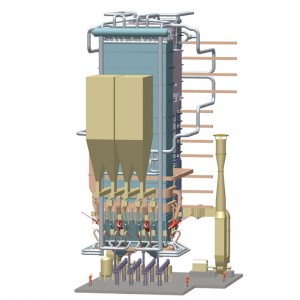

Flexibility Retrofit for Coal-fired Boilers

A Full Set of Flexibility Retrofit Solutions

Based on combustion system retrofit, this technology combines full load De-NOx retrofit, unit AGC coordination and steam temperature optimal control to forma full set of unique flexibility retrofit solutions to achieve the integrated boiler functions of high efficiency, stable combustion, denitration, anti-coking, and fuel flexibility. The retrofit proposal is customized suitable for different furnace types and based on the different customer demand.

-

Comprehensive Energy Conservation Technology for Coal-fired Units

Air-cushion Belt Conveying Technology Different from conventional belt coal conveyor, the Air-cushion belt conveyor replaces conventional rollers with an air cushion formed between the belt and the bottom plate to support the belt to significantly reduce resistance. The power consumption for coal conveying can be reduced by 20%~30%. The maintenance cost can be reduced by 85%. Besides, there is a 2-3 times lifetime increase. In 2023, this technology was applied in Xinjiang Wudong Coal Min... -

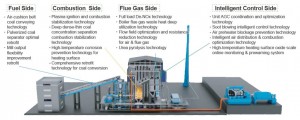

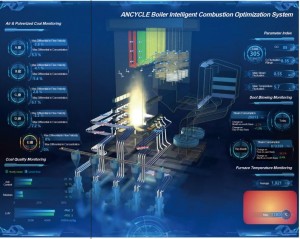

Overall Solution of Intelligent Thermal Power Plant

High-temperature Heating Surface Oxide Scale Online Monitoring & Prewarning System This technology realizes intelligent online monitoring for wall temperature distribution, oxide scale thickness, and tube lifetime. After application, the unplanned outage times caused by overheating tube explosions of the unit can be decreased greatly. Intelligent Air Distribution & Combustion Optimization Technology This technology realizes quantification of the air distribution system, real-time onli... -

Integrated Control Technology for High Temperature Corrosion on Boilers

High temperature corrosion problem has become a common problem in many large coal fired power plant boilers. It causes boiler water wall becoming thinner leading to pipe leaking and explosion accidents. According to the survey, the repair downtime of the domestic units of which the capacity are 300MW and above caused by pipe explosive accounts for about 40%. Therefore, high temperature corrosion not only affect the safe operation of the boiler, but also causes huge economic loss. The integrated high temperature corrosion control technology of LY Power can solve this problem effectively. The technology including three parts as follow.

-

Biomass Co-firing Technology for Coal-fired Power Plant

Biomass used as fuel for power and heat producing in coal-fired units, with advantages of lower carbon emission, clean and environmental protection, can promote environmental friendly and robust economic development and implement the plan on prevention and control of Atmospheric Pollution. As renewable energy alternative to coal-fired heating, biomass is good for environmental protection and climate change by reducing the need for coal, it can also promote the extension of the agricultural industry chain. Biomass is a kind of sustainable, clean and renewable energy source, which enjoys great market potential.

-

Ammonia Co-firing Technology for Coal-Fired Boilers

The “Ammonia-Coal Co-firing Technology for Coal-Fired Boilers” developed by Yantai Longyuan successfully achieved the pilot-scale verification of a 35% ammonia blending ratio (by heat capacity) in a 40MW coal-fired boiler for the first time in the world. This technology enabled a carbon emission reduction rate of over 35%, with NOₓ emissions better than those of pure coal-firing conditions and an ammonia burnout rate of 99.99%. Ammonia co-firing technology for coal-fired boilers developed by Yantai Longyuan has entered the world-leading ranks.