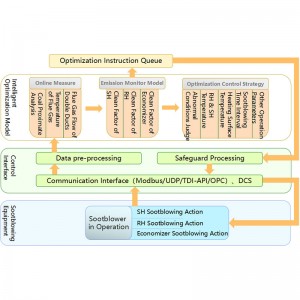

Intelligent Sootblowing Optimization Control System for Boiler

Product Features

Reduce the operation frequency of soot blower by about 20 ~ 40%

Reduce soot blowing steam consumption by about 20 ~ 40%

Reduce boiler exhaust flue gas temperature by 2℃~ 6℃

Improve boiler efficiency by 0.15% ~ 0.5%

The annual economic benefit of the unit is about 450000 ~ 700000 RMB

Improve main / reheat steam temperature and desuperheating water flow

Reduce tube wall abrasion of heating surface

Prolong the service life of heating surface and soot blower

Prevent serious dust accumulation or coking accidents

Write your message here and send it to us