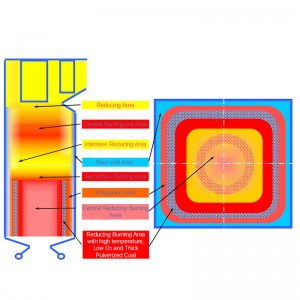

Dual-scale Low NOx Combustion Technology for T-firing Boilers

Combined with partition optimization and debugging method, the 3-field characteristics formed on the two scales can truly realize the function of anti-slag, excellent performance of stable combustion and large NOx emission reduction.

Main combustion air nozzles

Separated over fire air nozzles

Product Features

The significant reduction (around 40%~60%) of NOx with high burning rate. Boiler efficiency remains unchanged

Boiler defects like deviation of flue gas temperature, slagging, high temperature corrosion, high carbon content in ash, high exhaust gas, etc can be solved during retrofit of Low-NOx Combustion Technology.

Realization of low oxygen running without lowering boiler efficiency.

The integration of plasma ignition with speeding up the burning of pulverized coal and fuel oil saving for start up.

Improved the low load combustion stabilization and the reliability of the boiler operation.

Simple structure, easy construction, flexible operation.

Less initial investment, one-time retrofit investment, no running cost.

Retrofit period is short, usually accomplished in one overhaul time.

System Composition

By March 2020, Dual-scale Low-NOx Combustion Technology has been applied on more than 560 boilers.