Boiler Combustion Technology

-

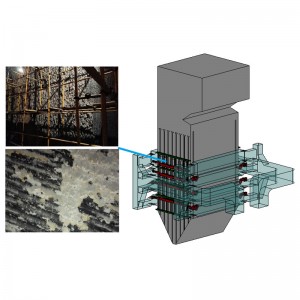

Integrated Control Technology for High Temperature Corrosion on Boilers

High temperature corrosion problem has become a common problem in many large coal fired power plant boilers. It causes boiler water wall becoming thinner leading to pipe leaking and explosion accidents. According to the survey, the repair downtime of the domestic units of which the capacity are 300MW and above caused by pipe explosive accounts for about 40%. Therefore, high temperature corrosion not only affect the safe operation of the boiler, but also causes huge economic loss. The integrated high temperature corrosion control technology of LY Power can solve this problem effectively. The technology including three parts as follow.

-

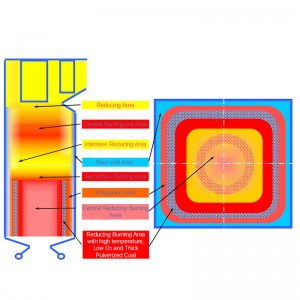

Dual-scale Low NOx Combustion Technology for T-firing Boilers

Dual-scale low NOx combustion technology advances in achieving differentiation of characteristics 3-field (temperature, air and concentration of pulverized coal, orbit of moving coal particle) in relevant zone in spatial scale through modification of combination of furnace combustion jet stream as well as achieving differentiation of characteristics 3-field in relevant nodal point zone during process scale (the 3-field characteristics on the two scales are different from other zones).

-

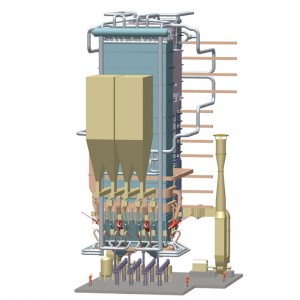

Low NOx Emission Technology for CFB Boilers

The technology is based on the concept of high efficiency and low ammonia combustion inside the furnace, supplemented by SNCR denitration outside the furnace, and advocates the combination of rational use of fuel and pollution control technology, combustion control technology and flue gas denitrification technology, so as to achieve high efficiency and low cost of NOx ultra-low emission through comprehensive prevention measures.