Integrated Control Technology for High Temperature Corrosion on Boilers

Product Features

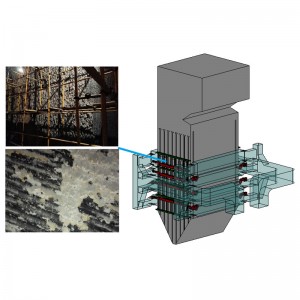

Near-wall air technology

Combustion of pulverized coal under oxygen deficient conditions produces CO, which is the main reason for the formation of reducing atmosphere. When the H2S concentration in flue gas is more than 0.01%, it will produce strong corrosion effect to the boiler water wall tube, so the H2S and CO content in the near-wall area has directly affected the degree of high-temperature corrosion. Therefore, it is necessary to introduce a flow of air in the high temperature corrosion region to increase the oxygen concentration, and consume the H2S and CO in the near-wall region to improve the reducing atmosphere in the water-cooling wall region. By adding a near-wall air nozzles, the near-wall air enters the furnace through the nozzle and forms a layer of oxide "protective film" in the near-wall area which destroys the reducing atmosphere and consumes H2S. Meanwhile, the "protective film" can reduce the water wall temperature in this area.

Combustion equipment retrofit.

The unburnt pulverized coal with sharp edges and corners has considerable wear effect on water wall. It destroys the less robust protective film formed by the corrosion products. The flue gas medium reacts rapidly with the pure metal. This combination of corrosion and wear can greatly aggravate the process of metal pipe damage. To fundamentally improve this phenomenon of flame flushing water wall, it is necessary to optimize the combustion equipment of the boiler and change the jet flow rigidity,angle, swirl intensity and other parameters. The uniformity of pulverized coal air should be enhanced and the pulverized coal flow of each burner should be equal, so as to ensure equal momentum of pulverized coal air, proper fineness of pulverized coal, and stable combustion.

High temperature corrosion protective coating technology.

The new inorganic material for heat insulation coatings, which LY Power developed with Chinese Academy of Sciences, applies nanoparticle technology, compound emission agent technology, system binder technology and it has the characteristics of high emissivity, high thermal conductivity, resistance to fouling and slagging, resistance to high temperature corrosion, and improvement of wear resistance. Spray the new material for heat insulation coatings on the heating surface of the substrate to protect the substrate's heating surface from oxidation, corrosion and coking, and improve the heat exchange efficiency of the equipment. After the application of this technology, it can be guaranteed that the surface emissivity is stable above 0.9 when the heating surface is in the high temperature environment. At the same time, the coating enables the surface to have a stable and durable high emissivity within the wide infrared spectrum. Its property of anti-slagging (self-cleaning) can greatly improve the heat transfer performance (enhance radiation heat transfer and heat conduction).

At present, the technology has been applied to unit#1 and #2 of Guodian Feixian power plant and unit #6 of Guodian Jingmen power plant

Product Features

The design of near-wall air nozzle is suitable for various furnace and various water wall tube.

Optimization and reconstruction design of burners and secondary air nozzles.

Ensure low NOx emission of coal fired boiler unit without any high-temperature corrosion occur in the boiler water-cooling wall at the same time.