Intelligent Control Technology

-

AGC Coordination and Steam Temperature Optimization Control System

The predictive control technology based on online model identification is used to replace the traditional “feedforward + PID feedback” control mode to realize AGC control and coordinated control between the boiler and the turbine. At the same time, factors influencing steam temperature like unit load, flue gas volume, coal feed rate, secondary air volume, feed water temperature are considered and identified to form a disturbance model. With this model, lag and stability problems will be solved. Besides, tracking performance of the unit will be improved so that important parameters such as steam pressure and steam temperature will be better controlled.

-

Intelligent Sootblowing Optimization Control System for Boiler

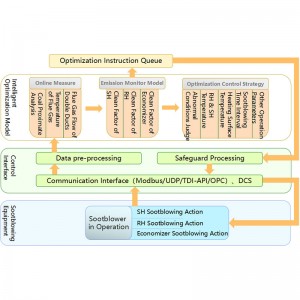

Based on advanced technologies of soft sensor modeling, online monitoring and diagnosing, dynamic compensation , it can be realized for quantifying and visually monitoring the heating surface pollution degree and optimizing soot blowing. By optimizing the operation area and frequency of sootblowers, the overall heat absorption distribution ratio of heating surface tends to be reasonable. In our system , the sootblowing process will be for actual demand, not for fixed time and quantity like before. Accident caused by unreasonable sootblowing can be effectively avoided and the pipeline life can be prolonged. It also can be achieved for energy saving, consumption reduction and economic and safety improvement of unit operation.