Overall Solution of Intelligent Thermal Power Plant

High-temperature Heating Surface Oxide Scale Online Monitoring & Prewarning System

This technology realizes intelligent online monitoring for wall temperature distribution, oxide scale thickness, and tube lifetime. After application, the unplanned outage times caused by overheating tube explosions of the unit can be decreased greatly.

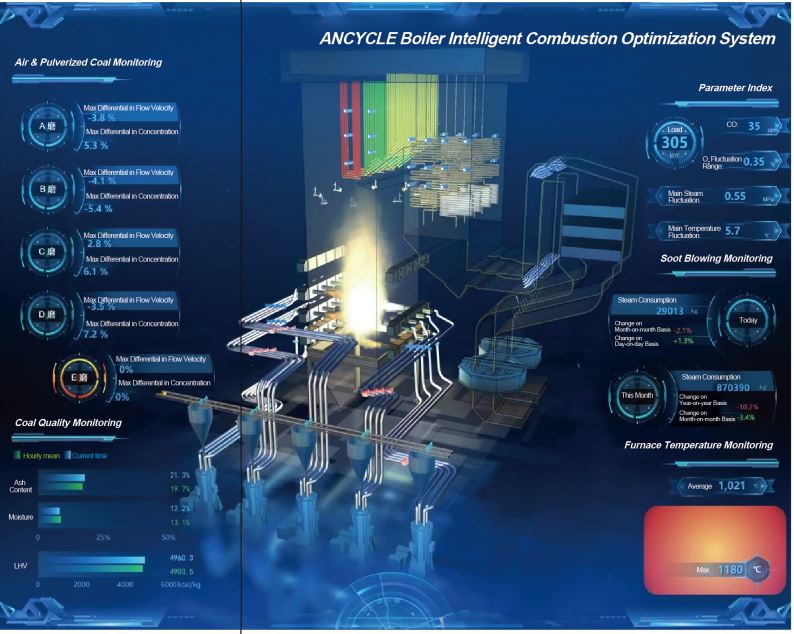

Intelligent Air Distribution & Combustion Optimization Technology

This technology realizes quantification of the air distribution system, real-time online monitoring of the combustion temperature distribution in the furnace, and fine control of the NOx generation amount in the full load of the boiler, ensuring the long term optimal balance of the furnace outlet thermal load, combustion efficiency, etc. Under variable operation conditions, it solves the defects like unstable combustion, deflective flame, high-temperature corrosion on heating surface, slagging and other issues, and provides decision-making basis for intelligent combustion of the unit.

Boiler Ash Deposit Online Monitoring and intelligent Soot Blowing Technology

Different from the traditional soot blowing in regular time and intensity, the new soot blowing system is conducted according to actual ash deposit status to realized accurate and intelligent operation. It deceases the frequency of soot blowing input, reduces high-quality steam consumption, improves boiler efficiency, optimizes heat transference of heat surface, and extends service life of tubes. Besides, it enhances the safety and flexibility of the whole soot blowing system.

Reduce the operation frequency of soot blower by about 20 ~ 40%

Reduce soot blowing steam consumption by about 20 ~ 40%

Reduce boiler exhaust flue gas temperature by 2℃~ 6℃

Improve boiler efficiency by 0.15% ~ 0.5%

The annual economic benefit of the unit is about 450000 ~ 700000 RMB

Improve main / reheat steam temperature and desuperheating water flow

Reduce tube wall abrasion of heating surface

Prolong the service life of heating surface and soot blower

Prevent serious dust accumulation or coking accidents

AGC Coordination and Steam Temperature Optimization Control System

The predictive control technology based on online model identification is used to replace the traditional “feedforward + PID feedback” control mode to realize AGC control and coordinated control between the boiler and the turbine. At the same time, factors influencing steam temperature like unit load, flue gas volume, coal feed rate, secondary air volume, feed water temperature are considered and identified to form a disturbance model. With this model, lag and stability problems will be solved. Besides, tracking performance of the unit will be improved so that important parameters such as steam pressure and steam temperature will be better controlled.

1.AGC operation speed and load control accuracy can reach 2.0% / min and 0.3%

2.Pressure and temperature of main steam are more stable, for stable condition:± 0.1-0.2mpa /± 2 ℃ and for variable load condition: ±0.4MPa /±6℃

3.The set value of main steam temperature is raised to 5-8℃, and the main steam pressure operates in strict accordance with the sliding pressure curve

De-NOx & De-SOx Optimization and Air Preheater Blockage Prevention Technology

LY Power provides an overall solution of “De-NOx optimization in furnace, NOx monitoring at SCR outlet, ammonia total input/zoning optimization control and air preheater blockage prevention” to solve the problems of large ammonia escape and air preheater blockage. Combined with frequency conversion retrofit for De-SOx slurry circulating pump, wast water intelligent control and ultra-clean liquid membrane device, energy conservation and consumption reduction for De-SOx system can be realized.