Mini Oil Ignition & Combustion Stabilization System

MOIS is a technology that can largely reduce fuel oil consumption during boilers operations such as startup, shutdown, low load regulating operations. It can directly ignites pulverized coal with mini amount of fuel oil at the initial stage of pulverized coal entering the burner when there is no flame in the furnace so as to achieve purpose of oil saving .

Principle

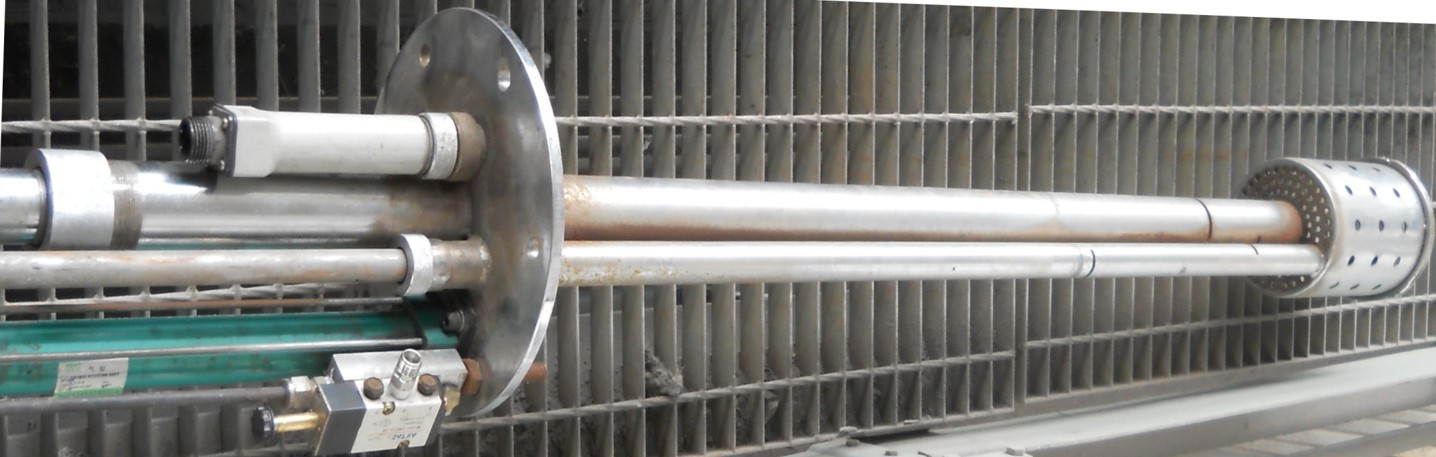

The working principle of Mini-oil ignition is as follows: the oil is crushed and atomized into ultrafine oil droplets in the oil gun through atomizing medium or under oil pressure, and then it will be ignited by the ignition gun. Through reasonable air distribution and stable combustion design, a flame of stable combustion and strong rigidity is to be formed in the oil combustion device. The central temperature of the flame is as high as 1300-1500℃. As a high-temperature flame core, it will ignite the pulverized coal directly in the pulverized coal burner. And the temperature of the concentrated phase pulverized coal particles entering the primary chamber rises sharply, and a large amount of volatile is to be released when the coal particles being broken and crushed, realizing rapid ignition and combustion.

System Composition

Ignition and combustion system:

Mini oil gun & coal burners. During the process of the boiler startup, shutdown and low load operation, Mini-oil ignition coal burners are to ignite the pulverized coals under the cold state of boiler, while its coal flame can support the furnace stable combustion when boiler load is below the minimum stable load. During the normal operation of boiler, the Mini-oil coal burners will act as the main burners and the performance of the original coal burners will be maintained.

Cold Air Heating System:

Install steam air heater or mini oil gun to heat the primary air for purpose of warming up the mill.

Control & Monitoring System

Mini-oil ignition control system, flame-image monitoring system, burner wall monitoring system.

Benefits

Economic

Oil saving, Significant oil saving performance as compared to conventional ignition method.(Generally 60-90% oil-saving can be achieved, this depends on the oil consumption, coal quality and operation level)

Improve the load regulation performance

Provide more opportunities and conveniences for renewable energy such as wind power and solar power to synchronize, and play an important role in optimizing power supply structure and reducing greenhouse gas emissions.

Less maintenance as compared to conventional oil gun system.

The successful application in more than units demonstrates the reliability of the MOIS. Compared to traditional oil guns, MOIS require less frequent and simpler maintenance, thereby reducing potential risks to maintenance personnel.

Environmental protection

Avoid the black smoke problem caused by not being able to use ESP during oil ignition.

Low Nox. The Mini-oil burner itself is a kind of low NOx burner with characteristics of deep staged air and fuel, deep separation of rich and lean coal and deep separation of primary air.

Reduce coal ash emission. After MOIS application, ESP can be put into operation to eliminate dust emission during boiler ignition, shutdown and low load combustion stabilization process.

Applications

After more than 20 years of development, MOIS has now become a very mature technology, bringing significant economic benefits to customers. MOIS is applicable to Wall‐fired and Corner‐fired boilers and W-fired boilers, and also can be smoothly used on both storage and direct fired pulverizing systems.

Up to April, 2024, MOIS has been applied on more than 600 projects with capacity ranging from 20MW to 1000MW

MOIS Projects out of China

| Item | Name | Unit Capacity | Retrofit/New | Wall/ Tangential | Coal Type |

| 1 | India Jhajjar CLP | 2x600MW | New | T-fired | High-ash coal |

| 2 | India Adani | 12x600MW | Retrofit | T-fired | High-ash coal |

| 3 | Cambodia Sihanouk Port | 3x135MW | New | T-fired | High-moisture coal |

| 4 | Indonesia Jeneponto | 2x125MW | New | T-fired | High-moisture coal |

| 5 | Indonesia East Kalimantan | 1x60MW | New | T-fired | High-moisture coal |

| 6 | Parkistan Ruyi | 2x660MW | New | T-fired | Bituminous |

| 7 | Tajikistan Dushanbe | 2x50MW | New | T-fired | Bituminous |

| 8 | Turkey Hurutu | 2x660MW | New | T-fired | Bituminous |

| 9 | Zimbabwe Hwange Phase III | 2x335MW | New | T-fired | Bituminous |