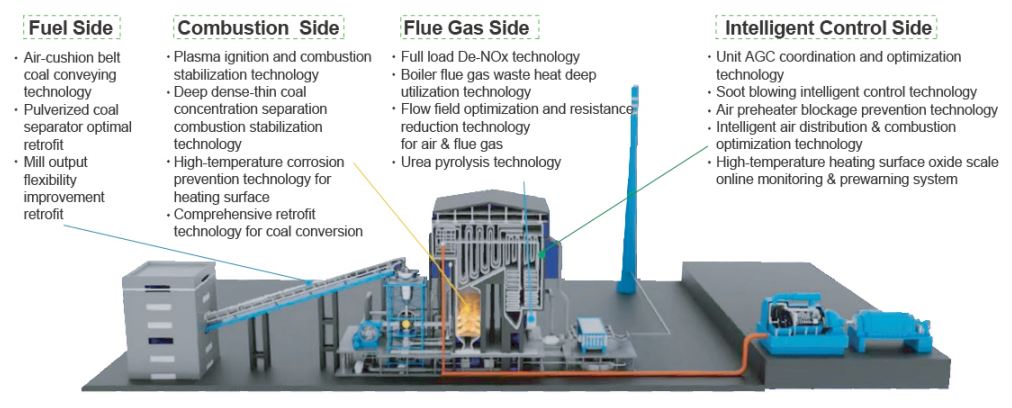

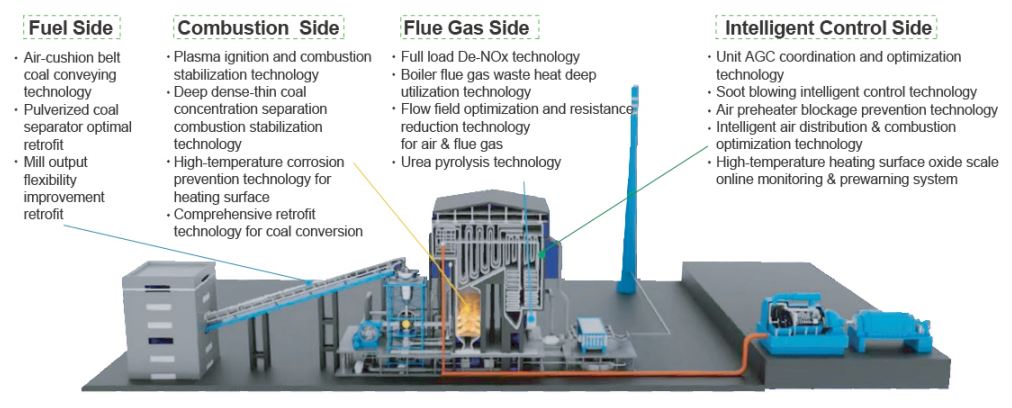

Flexibility Retrofit for Coal-fired Boilers

Coal Conversion Comprehensive Retrofit Technology for Coal-fired Boilers

For each coal conversion project, a practical and comprehensive retrofit solution for the customer will be developed through in-depth study of boiler operation status, combined with numerical simulation and thermal calculation. The fuel cost for the power plant can be significantly reduced. At present this technology has been applied successfully on a number of power plants like Hanchuan TPP, Chizhou TPP , Fengcheng TPP, etc.

High-temperature Corrosion Prevention Technology for Heating Surface

This technology can improve the reducing atmosphere near the water wall and prevent the high-temperature corrosion effectively. It has been successfully applied on over 20 boilers.

Preventive effect: low-temperature solid phase sintering technology for water-based ceramic matrix slurry is applied to form a layer of gradient protective composite film on the heating surface of the boiler to achieve protection of it.

Elimination effect: near-wall membrane air technology combined with combustion optimization technology are applied to eliminate high-temperature corrosion in boilers.

Peak Load Regulation Technology with Electric Boiler

In this technology, the electric boiler with heat storage function is arranged in thermal power plant to realize heat & power decoupling, accommodate clean energy and enhance heat supply capacity. The electric boiler is an energy conversion device that converts electric energy to thermal energy and transfers thermal energy to the medium. In principle, the current passes through electrodes and contacts with water to generate hot water or steam, and its power can be regulated instantly in line with power grid demands. This technology has realized successful industrial application.

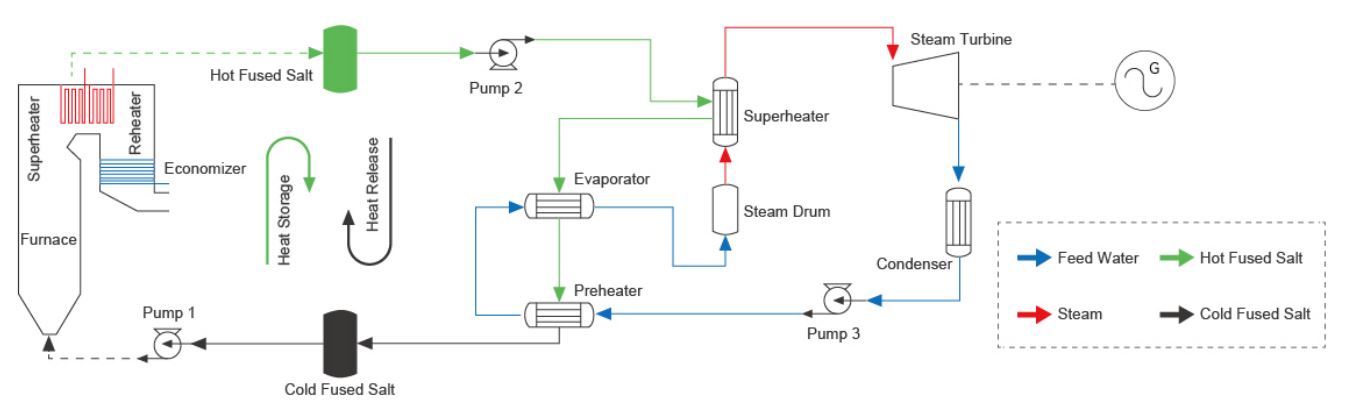

Molten Salt Energy Storage Technology

This technology can effectively solve the contradiction of boiler combustion in low load or steam supply in high load with peak load regulation requirement from power grid. A set of high-temperature molten salt energy storage system is integrated into the boiler-turbine thermal system to store heat from excess high-temperature steam generated by the boiler and return it to the turbine power generation system according to power gird demands or to meet the steam supply demand of the unit. After retrofit, the operation of the boiler can be decoupled with that of steam turbine, further improving the deep peak load operation capability of the units.