Dual-scale Low NOx Combustion Technology for Coal Fired Boilers

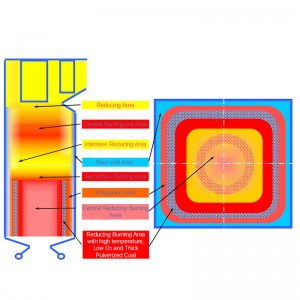

Dual-scale low NOx combustion technology advances in achieving differentiation of characteristics 3-field (temperature, air and concentration of pulverized coal, orbit of moving coal particle) in relevant zone in spatial scale through modification of combination of furnace combustion jet stream as well as achieving differentiation of characteristics 3-field in relevant nodal point zone during process scale (the 3-field characteristics on the two scales are different from other zones).

Combined with partition optimization and debugging method, the 3-field characteristics formed on the two scales can truly realize the function of anti-slag, excellent performance of stable combustion and large NOx emission reduction.

SOFA (separated over fire air) is induced from secondary air box with a proportion of 20%~30%. SOFA nozzles can swing both in vertical and horizontal. Promote coal burning out. Control temp. of flue gas at furnace outlet. Adjust the flue gas temp. deviation.

Main combustion air nozzles

Separated over fire air nozzles

LNC Coal Burner

Swing in veritcal direction

- Adjust the position of flame center

Pulverized coal dense-thin separation

- Fuel staging to reduce NOx

- Stabilize combustion

Blunt body structure

- Entrain flame to stabilize combustion

Separated over fire air nozzles

Product Benefits

The significant reduction (around 40%~60%) of NOx with high burning rate. Boiler efficiency remains unchanged

Boiler defects like deviation of flue gas temperature, slagging, high temperature corrosion, high carbon content in ash, high exhaust gas, etc can be solved during retrofit of Low-NOx Combustion Technology.

Realization of low oxygen running without lowering boiler efficiency.

The integration of plasma ignition with speeding up the burning of pulverized coal and fuel oil saving for start up.

Improved the low load combustion stabilization and the reliability of the boiler operation.

Simple structure, easy construction, flexible operation.

Less initial investment, one-time retrofit investment, no running cost.

Retrofit period is short, usually accomplished in one overhaul time.

Application

By the end of 2023, it has been applied on over 580 boilers.

Project Reference:Mawan Project

- Manufacturer: Harbin Boiler Company (HBC).

- 300MW subcritical T-firing boiler.

- Problems before retrofit: slagging, high NOx emission (550-700mg/Nm3) and high unburnt carbon in fly ash.

- Purpose: meet the Chinese government rules on NOx emissions.

- Performance after retrofit

- NOx Reduction: NOx concentration at furnace outlet is reduced to 170~250mg/Nm3 burning Dayou Coal (bituminous, Vad: 25~30%)and 128~180 mg/Nm3 burning Shenhua Coal (bituminous, Vad: 25~35%)

- Boiler Operation: After retrofit the boiler can operate without any slagging or high ash content in ash.

- Boiler Efficiency: Boiler efficiency was 91.5~93.2% before retrofit, after retrofit no negative impact showed to its efficiency