Comprehensive Energy Conservation Technology for Coal-fired Units

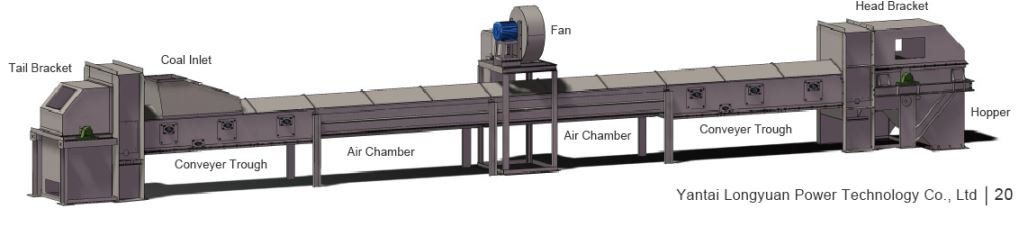

Air-cushion Belt Conveying Technology

Different from conventional belt coal conveyor, the Air-cushion belt conveyor replaces conventional rollers with an air cushion formed between the belt and the bottom plate to support the belt to significantly reduce resistance. The power consumption for coal conveying can be reduced by 20%~30%. The maintenance cost can be reduced by 85%. Besides, there is a 2-3 times lifetime increase. In 2023, this technology was applied in Xinjiang Wudong Coal Mine project and Yushuling Coal Mine project

Boiler Flue Gas Waste Heat Deep Utilization Technology

In this technology, high-efficiency heat exchanger is arranged in the tail duct of the boiler to recycle the waste heat from flue gas. The design of multiple stages recycling and air preheater bypass enables to realize cascade utilization of waste heat, which can reduce power generation coal consumption by 2-4g/kWh, alleviate air preheater blockage, reduce water consumption for De-SOx and improve the De-dust efficiency as well. It has been successfully applied on over 70 units with long term, leak free, safe and reliable operation.

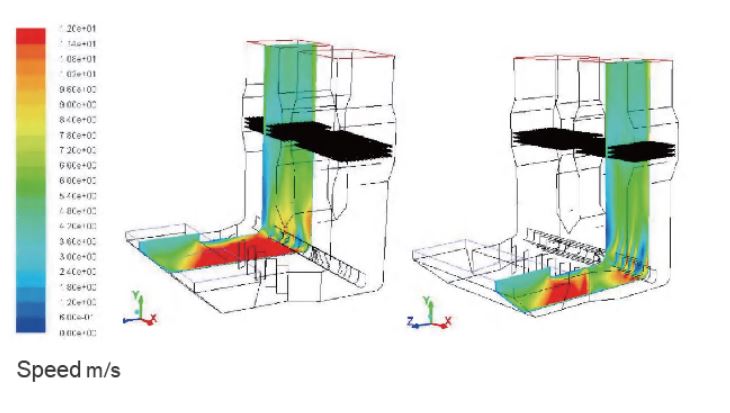

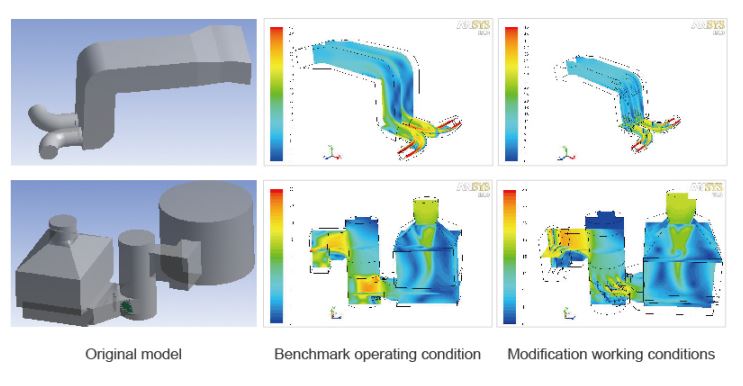

Flow Field Optimization and Resistance Reduction Technology for Air & Flue Gas

In response to the existing problems of resistance and flow field in air and flue gas ducts as well as the actual demands of target customers, perform 3D visualization on the medium flow process in the duct assisted with digital twinning technology. By arranging different forms of air deflector, modifying the shape of the bends, straightening the flue gas duct and other technical methods to improve flow field uniformity and reduce medium flow on-way resistance, energy conservation and consumption reduction can be realized. This technology has been successfully applied on 13 units

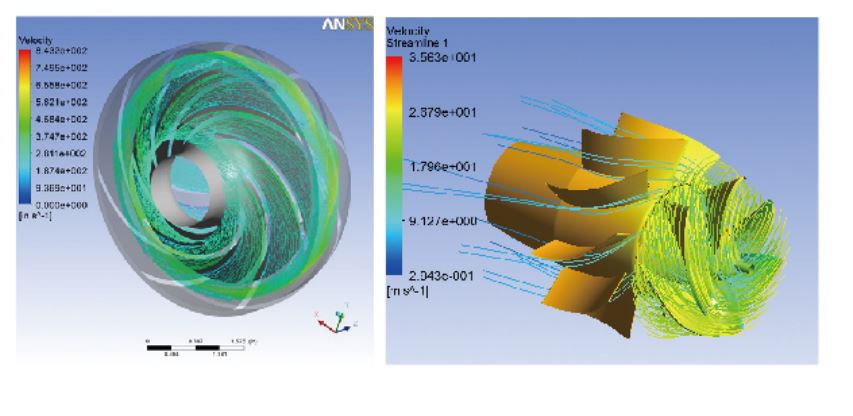

3D-flow High-efficiency Energy Conservation Technology for Pump Rotor

Relying on the large 3D-flow rotor database and CFD technology, perform optimal design for the rotor and guide vane of pump to significantly improve the pump flow and energy saving rate. The advantages of this technology include its wide applicability to various circulating pumps and its significant transformation effects. It has realized successful industrial application.

Boiler Tail Heating Surface Retrofit Technology

Apply retrofit on heating surface of economizer and air preheater to decrease the temperature of the flue gas, promote boiler efficiency and improve steam parameters, with due consideration to requirements for drying pulverized coal and SCR operating in low load. It has been successfully applied on over 30 units.