Coal Fired Unit Efficiency

-

Flexibility Retrofit for Coal-fired Boilers

A Full Set of Flexibility Retrofit Solutions

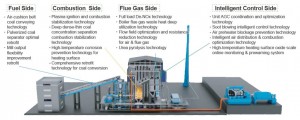

Based on combustion system retrofit, this technology combines full load De-NOx retrofit, unit AGC coordination and steam temperature optimal control to forma full set of unique flexibility retrofit solutions to achieve the integrated boiler functions of high efficiency, stable combustion, denitration, anti-coking, and fuel flexibility. The retrofit proposal is customized suitable for different furnace types and based on the different customer demand.

-

Comprehensive Energy Conservation Technology for Coal-fired Units

Air-cushion Belt Conveying Technology Different from conventional belt coal conveyor, the Air-cushion belt conveyor replaces conventional rollers with an air cushion formed between the belt and the bottom plate to support the belt to significantly reduce resistance. The power consumption for coal conveying can be reduced by 20%~30%. The maintenance cost can be reduced by 85%. Besides, there is a 2-3 times lifetime increase. In 2023, this technology was applied in Xinjiang Wudong Coal Min... -

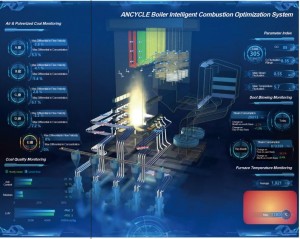

Overall Solution of Intelligent Thermal Power Plant

High-temperature Heating Surface Oxide Scale Online Monitoring & Prewarning System This technology realizes intelligent online monitoring for wall temperature distribution, oxide scale thickness, and tube lifetime. After application, the unplanned outage times caused by overheating tube explosions of the unit can be decreased greatly. Intelligent Air Distribution & Combustion Optimization Technology This technology realizes quantification of the air distribution system, real-time onli... -

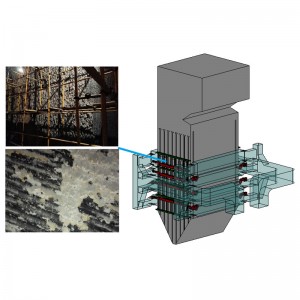

Integrated Control Technology for High Temperature Corrosion on Boilers

High temperature corrosion problem has become a common problem in many large coal fired power plant boilers. It causes boiler water wall becoming thinner leading to pipe leaking and explosion accidents. According to the survey, the repair downtime of the domestic units of which the capacity are 300MW and above caused by pipe explosive accounts for about 40%. Therefore, high temperature corrosion not only affect the safe operation of the boiler, but also causes huge economic loss. The integrated high temperature corrosion control technology of LY Power can solve this problem effectively. The technology including three parts as follow.