Biomass Co-firing Technology for Coal-fired Power Plant

There are three main technical models for the coupling biomass with coal-fired power plants, including coal-biomass co-combustion technology,biomass gasification coupling technology and biomass combustion coupling technology. Among them, coal-biomass co-combustion technology is direct coupling, and the other two are indirect coupling.

Regarding to these three technical routes of coupling biomass with coal-fired power plant the comparison is as below.

| Biomass Coupled with Power Plant Technology | Investment | System Complexity | Energy Utilization Efficiency | Impact on Boiler | Project Quantity | Blending Ratio(mass ratio) | Safety Performance |

| Coal-biomass Co-combustion Technology | low | simple | high | coking and high temperature corrosion of alkali element | Smaller | <15% | corrosion on heating surface |

| Biomass Gasification Coupling Technology | high | complicated | higher | less | larger | No limitation in theory | risk of explosion |

| Biomass Combustion Coupling Technology | high | more complicated | high | less | larger | No limitation in theory | safer |

The "Technology Research and Engineering Demonstration of Direct Biomass Co-firing in 1000MW Ultra-supercritical Coal-fired Boilers" project, undertaken by Yantai Longyuan for Shandong Shouguang Company, has solved key challenges in the safe storage, accurate measurement, and stable transportation of biomass powder fuel. It is China's first domestically developed 1000MW ultra-supercritical coal-fired power plant biomass co-firing engineering demonstration project with fully independent intellectual property rights, achieving an annual biomass fuel co-firing volume of up to 250,000 tons.

The project fully leverages the advantages of 1000MW ultra-supercritical coal-fired power units, including high energy efficiency and low pollutant emission concentrations. While realizing CO₂ emission reduction, it improves the utilization efficiency of biomass resources and reduces pollutant emissions during the utilization process.

In addition, the project plays a positive role in solid waste (vegetable waste) disposal and coal substitution. It can handle approximately 520,000 tons of vegetable waste annually, reduce coal consumption by 125,000 tons, and cut CO₂ emissions by 310,000 tons, thus demonstrating strong leading and exemplary significance.

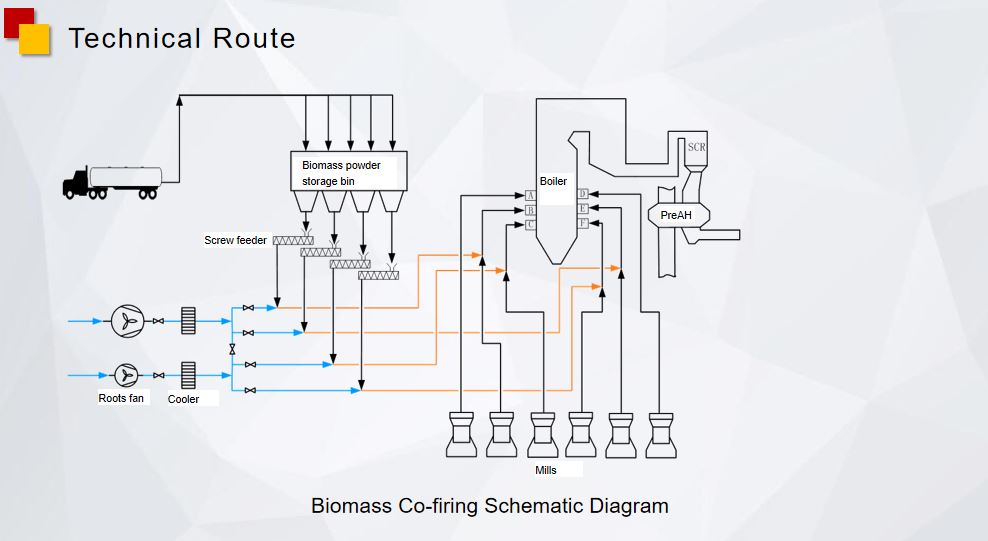

The main equipment of coal-biomass co-combustion system are biomass storage bunker, crusher, mill, biomass powder bunker (including induced draft fan and dust precipitator), biomass powder conveying system, biomass burner and the relative electrical thermal control system.

Coal-fired power plant of China Energy Ledong Power Company coupled waste-to-energy technology project

Waste Type: Household Waste (Calorific Value:1000kCal~4000kCal)

Waste Combustion Capacity: 30t/d

The biomass is burnt completely through the biomass incinerator, and the heat generated by the biomass combustion is used to heat high-pressure feedwater of boiler through the corresponding heat exchange. After the heat exchange, the high-pressure feedwater becomes steam with the same parameters as that of boiler. It is then sent to the steam turbine of the coal-fired unit for power generation.

The main equipment of biomass combustion coupling system are biomass storage bunker, biomass crushing system, biomass conveying belt and related feeding screw conveyor, biomass incinerator (circulating fluidized bed form), high-pressure heat exchanger, dust precipitator , fans, conveying pipelines and related electrical thermal control systems.