Ammonia Co-firing Technology for Coal-Fired Boilers

The "Ammonia-Coal Co-firing Technology for Coal-Fired Boilers" developed by Yantai Longyuan successfully achieved the pilot-scale verification of a 35% ammonia blending ratio (by heat capacity) in a 40MW coal-fired boiler for the first time in the world. This technology enabled a carbon emission reduction rate of over 35%, with NOₓ emissions better than those of pure coal-firing conditions and an ammonia burnout rate of 99.99%. Ammonia co-firing technology for coal-fired boilers developed by Yantai Longyuan has entered the world-leading ranks.

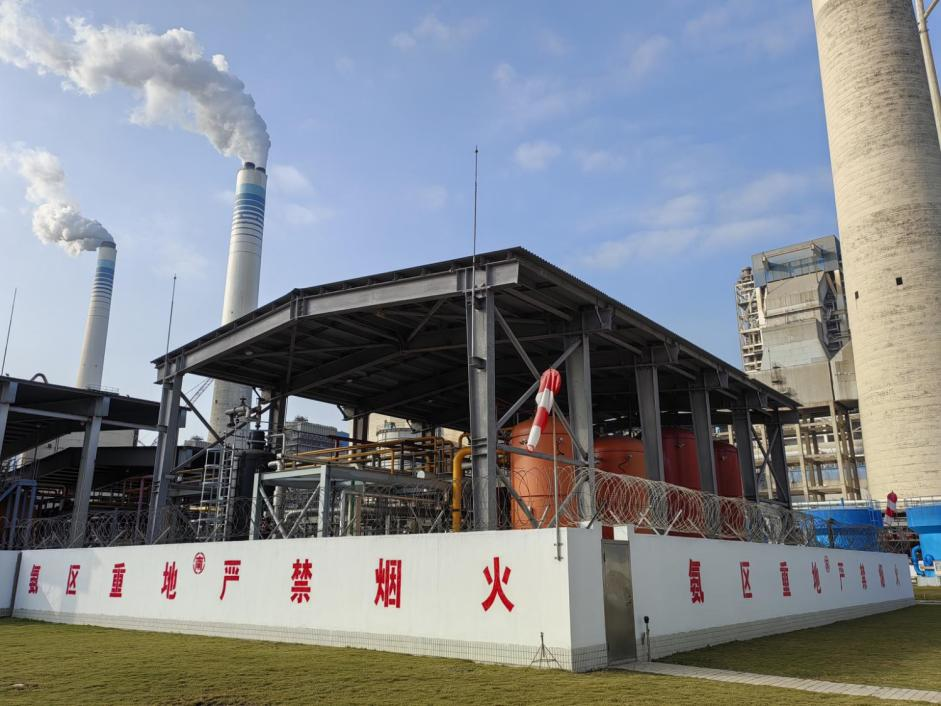

On-site photos of the 40MWth coal-fired boiler ammonia co-firing platform

The above in-situ picture shows the cofiring burner with the air and NH3 supply pipes. As seen, the white pipe above the burner is the SA pipe, the blue pipe is the PA pipe, and the yellow pipe is the NH3 gas pipe.

The above in-situ picture shows the NH3 supply system. The liquid NH3 in the storage tanks is transported to the vaporizer by ammonia pump. The vaporizer uses the hot water circulated from the boiler waterwall as the heat medium to vaporize the liquid NH3 into gaseous phase.

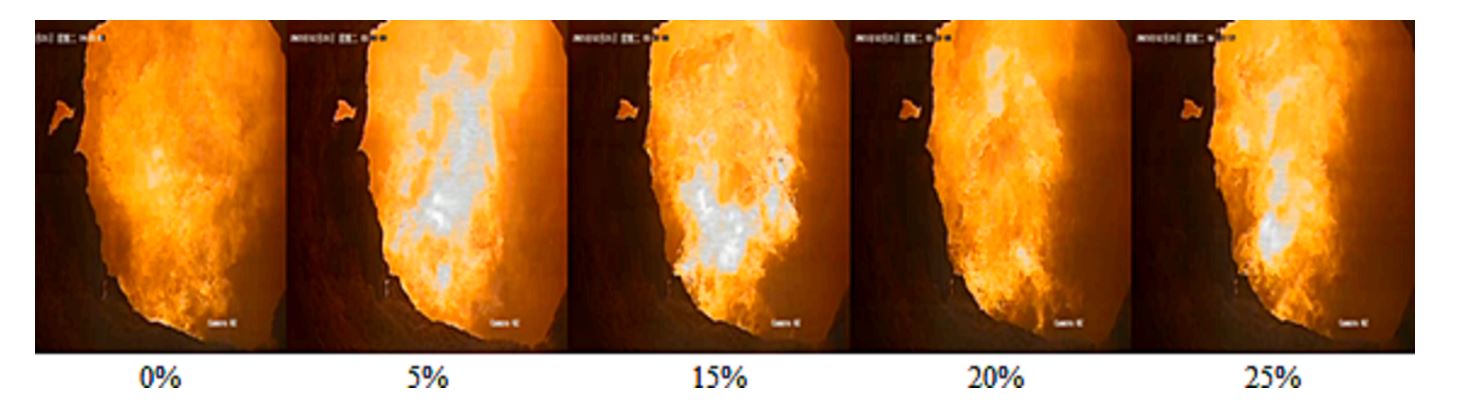

The above picture shows the flame images at the burner outlet taken by the boiler flame camera under different ammonia cofiring ratios. Bright flames could be observed under all ammonia cofiring ratios indicating that the cofiring burner designed in this study can achieve stable ignition and combustion consistently. Note that the flame is affected by strong turbulence at the burner outlet so that the flame brightness is constantly fluctuating. For this reason, the flame images that were taken at a single instance are not suitable to be used to compare the flame intensity under different ammonia cofiring ratios.

In 2024, Yantai Longyuan made a major breakthrough in the project "Research and Industrial Verification of Key Technologies for Ammonia Co-firing in 600MW Coal-Fired Boilers" at Unit 3 Boiler of Shenhua Guangdong Taishan Power Plant. The project realized ammonia co-firing with a 10% blending ratio (by heat capacity) at 600MW load and a 20% blending ratio (by heat) at 300MW load. During the test, the maximum ammonia injection amount reached 30 tons per hour, the boiler operated stably under ammonia-coal co-firing conditions, and the ammonia burnout rate hit 99.99%. The concentration of nitrogen oxides before the denitrification device was equivalent to that of pure coal-firing conditions, and there was no change in the emission concentration of flue gas pollutants or ammonia slip rate.

On-site photos of Guangdong Taishan Power Plant Project